Bob came back to us after first having his Z34 tuned. This time he came back for much more. Bob, Fast Intentions, and Specialty-Z came together to formulate a plan to turbocharge the Z. Fast Intentions has just recently began shipping their much anticipated twin turbo kit and we were the lucky ones to first install it.

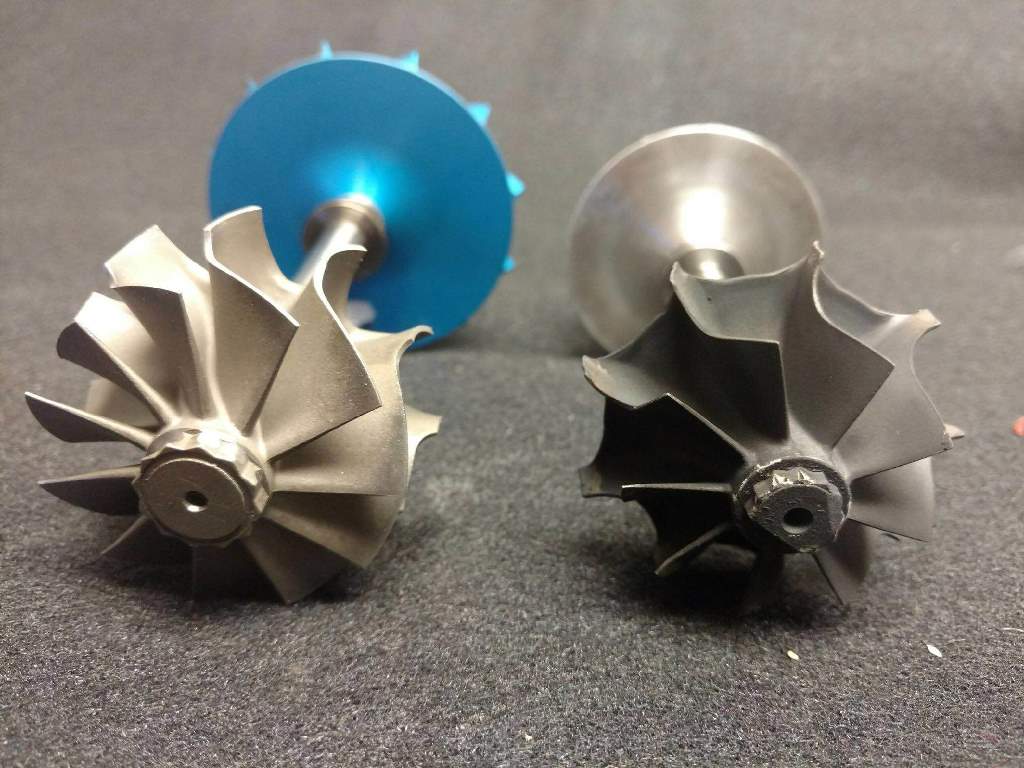

The kit is offered in different options dependent mainly on turbo size selection. All turbos used in the kit feature Tial .86 turbine housings made from SS cast for improved flow and heat enthalpy. This allows faster spool from the turbine. The base kit starts off with a pair of GT2860RS turbos. Followed by the Garrett GTX compressor wheel upgrades. Finally the Tial Alpha series (HTA) turbo as the creme de le creme for those looking past stock shortblock power handling capabilities.

The NISMO as it sat before its twinturbo adventure.

The VHR ready to leave its cozy engine bay.

Now its time to start disassembly to make way for our twinturbo parts!

With the intake manifold removed the stock fuel injectors and rails come out. We’ll be moving more air so we’ll need larger injectors.

Stock injector on the left and our new higher flowing 650 cc injector on the right. Appropriate adapters for the electrical connection are provided to make it simple plug n’ play affair.

Rails, injectors, and adapters installed.

With the intake manifold removed for the injectors install, we also replaced the factory DENSO spark plugs in favor of HKS Racing spark plugs.

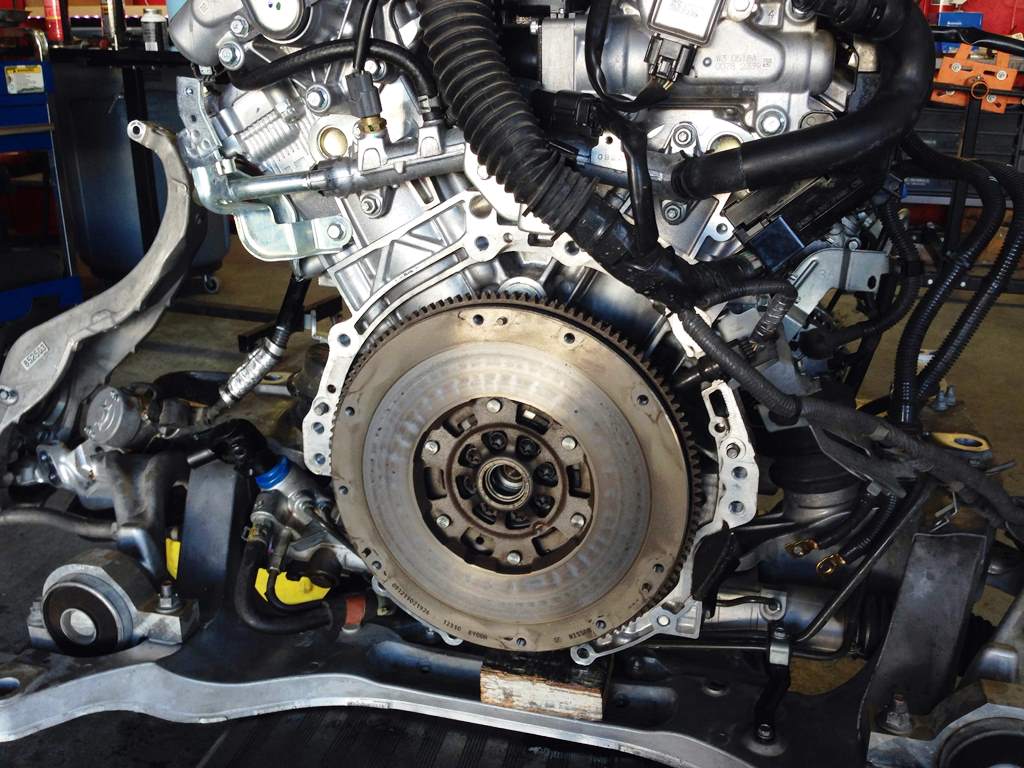

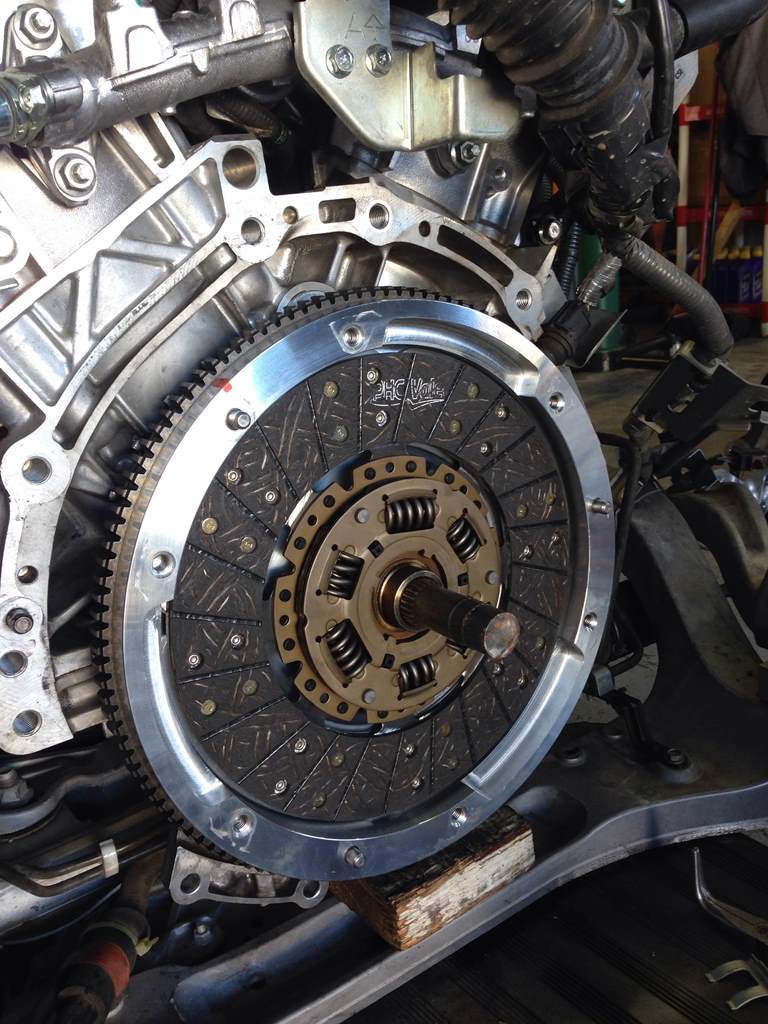

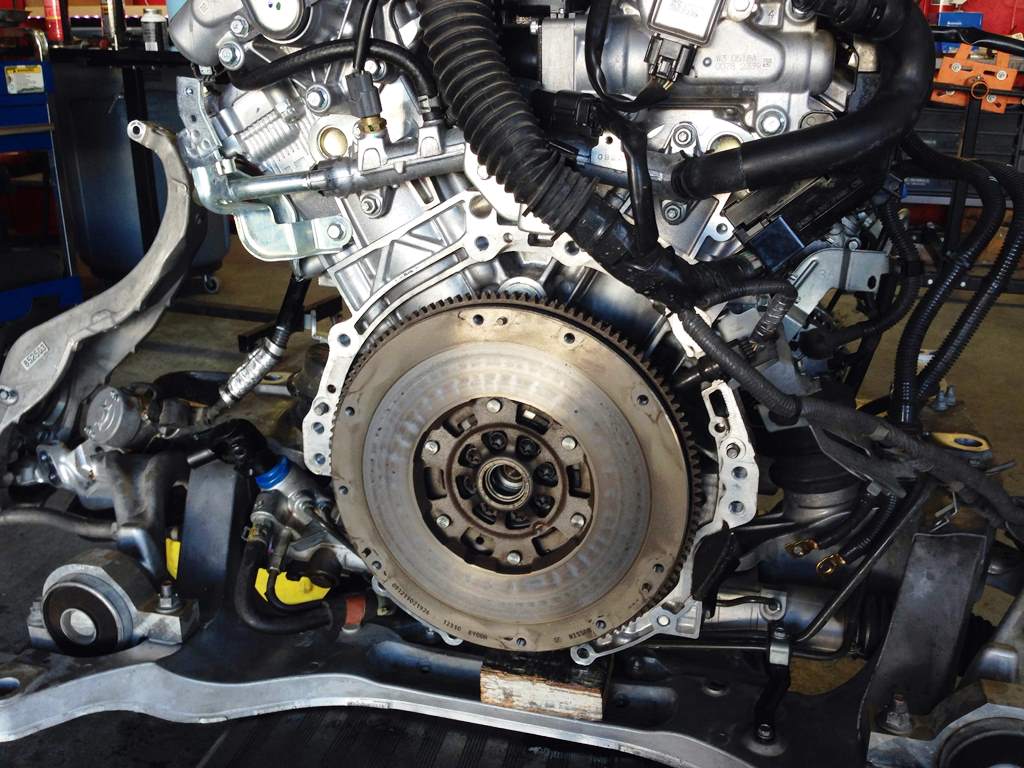

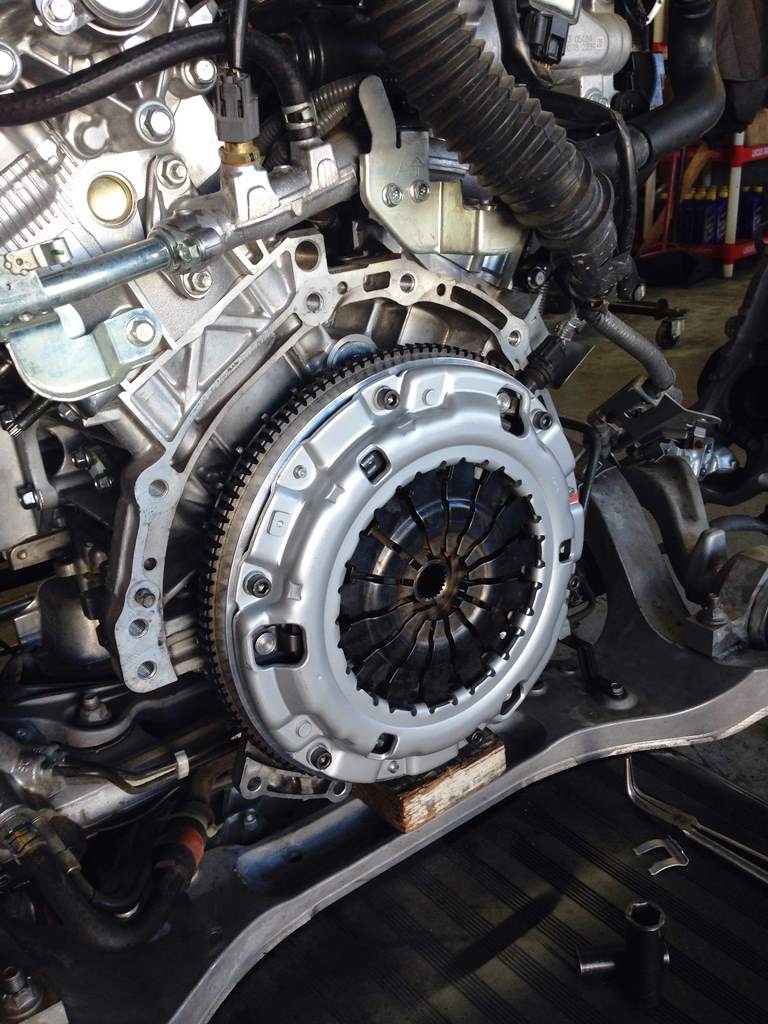

The stock Nissan clutch (disc shown on top of pressure plate). Since we’re going to be making more power and especially torque we removed the stock system and upgraded to the SZ Max Street Clutch & Flywheel Kit.

The heavy factory Nissan dual mass flywheel also gets ditched.

We took the opportunity to replace the rear engine main seal. This would also be the time to replace the pilot bushing that is included in our clutch and flywheel kit.

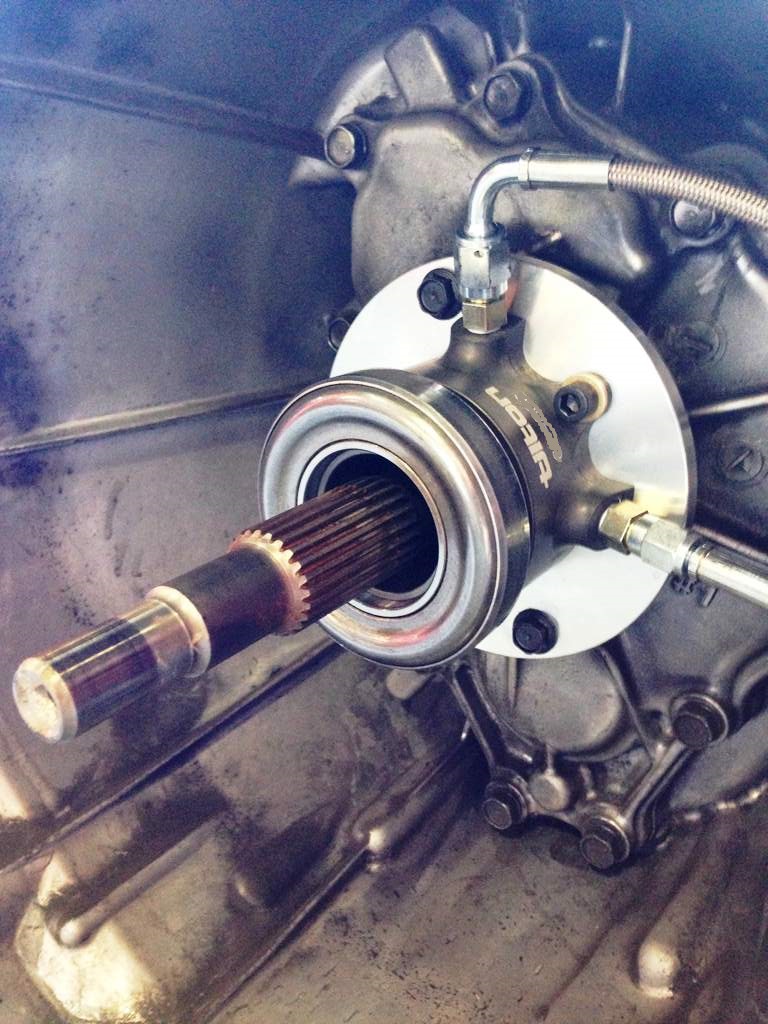

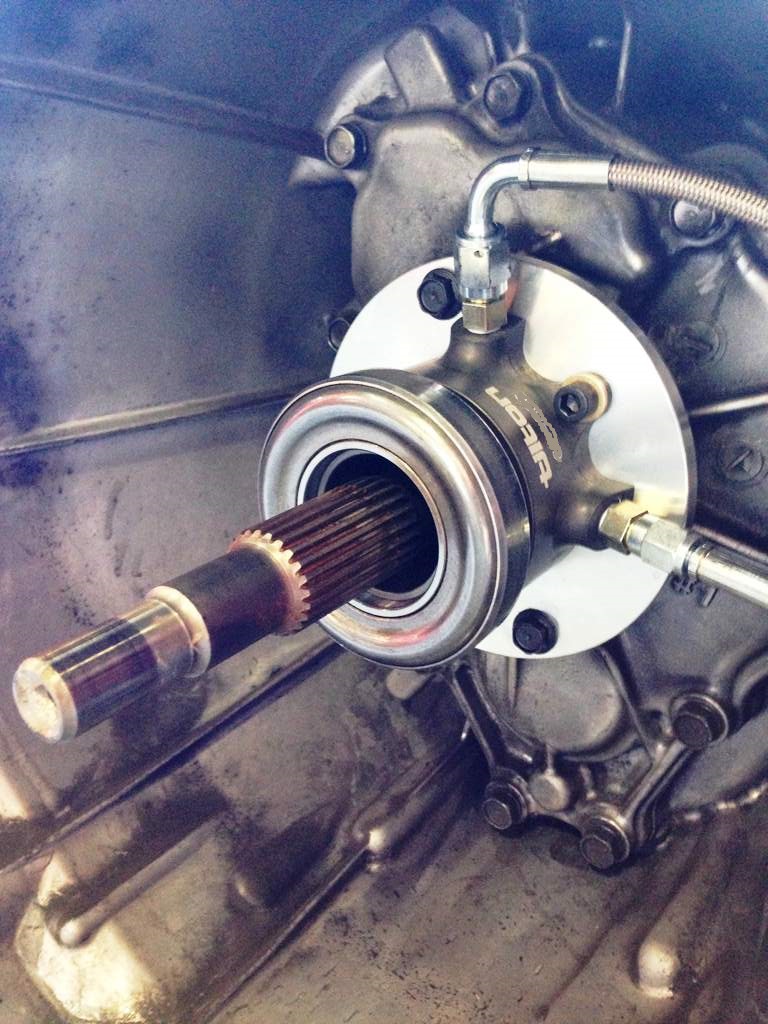

The factory cheesy Nissan slave cylinder & bearing get upgraded with our own piece also included in our kit.

Our upgraded slave & bearing assembly that includes SS lines and easy bolt in adapter plate.

Our piece installed, ready to go.

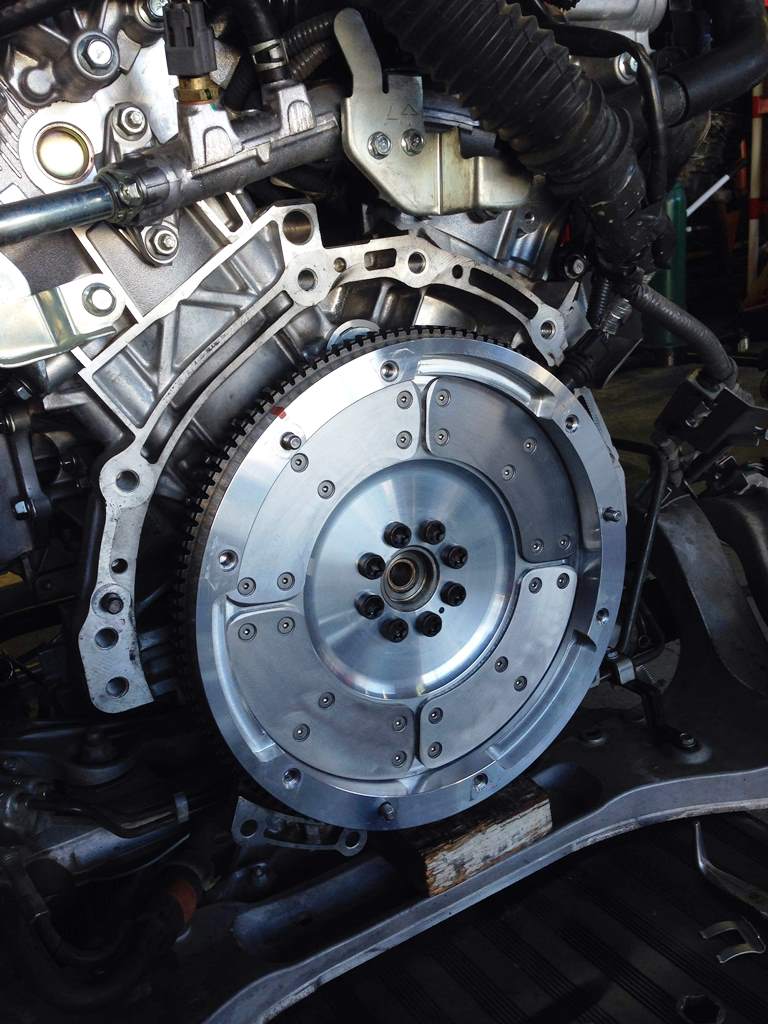

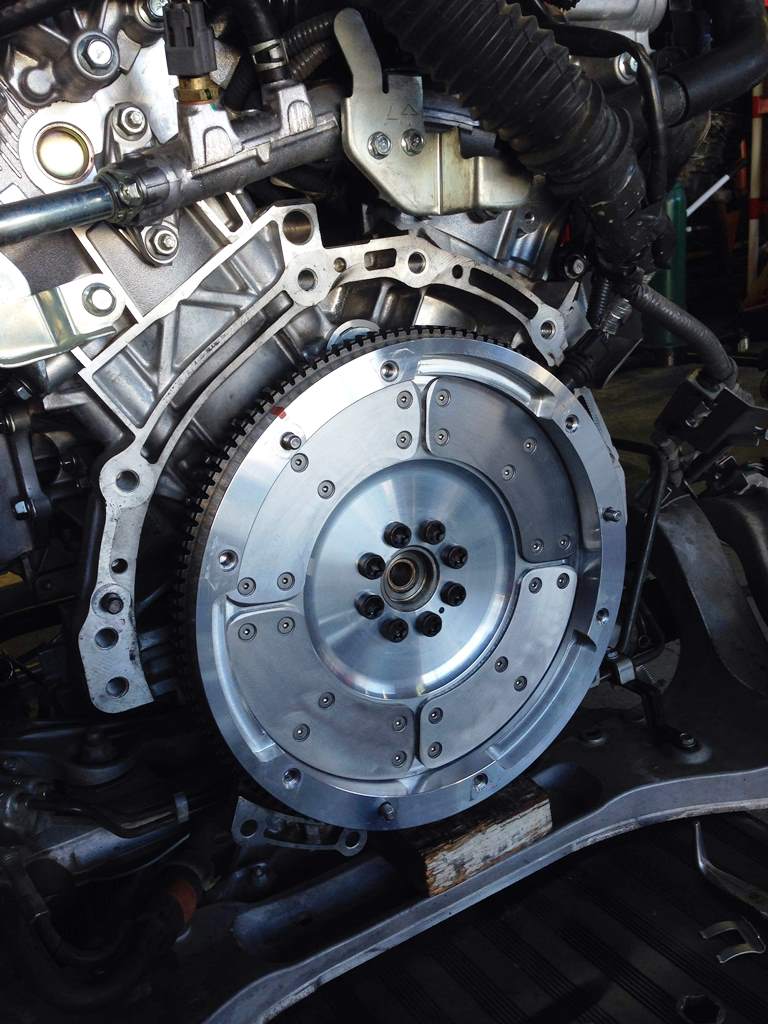

Our lightweight aluminum segmented flywheel bolted down.

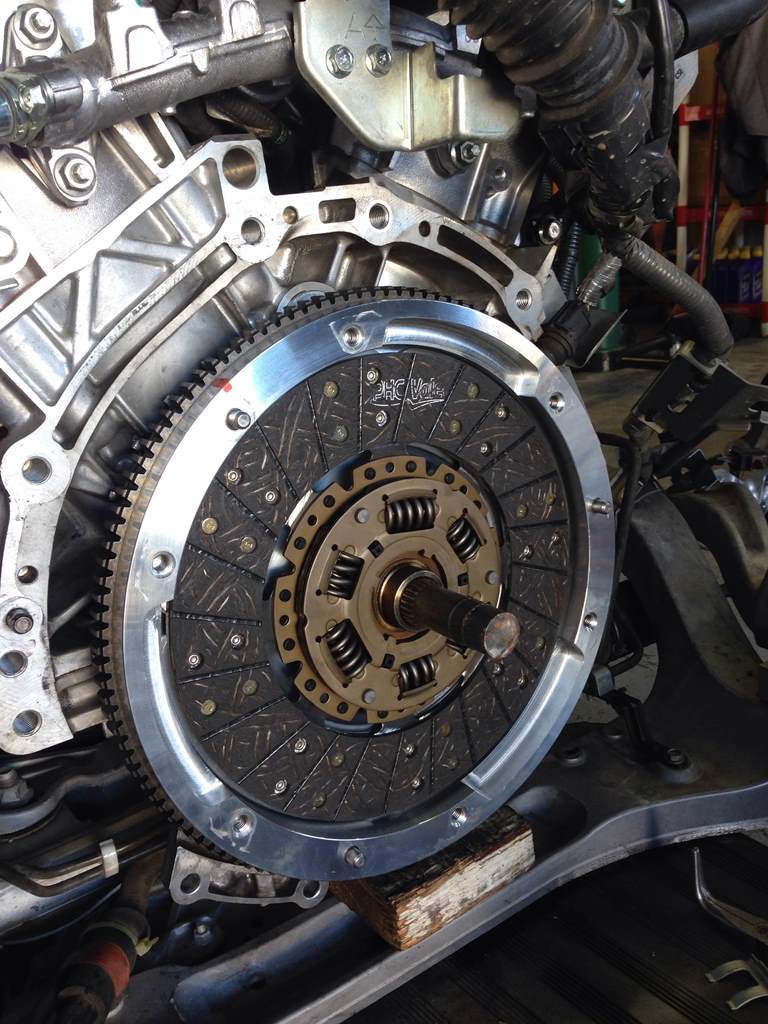

The Max Street kit uses a modified organic clutch disc for smooth engagements. Those looking to do more aggressive driving like drag launching and slipping will want to use our 6-Puck or 5-Puck options.

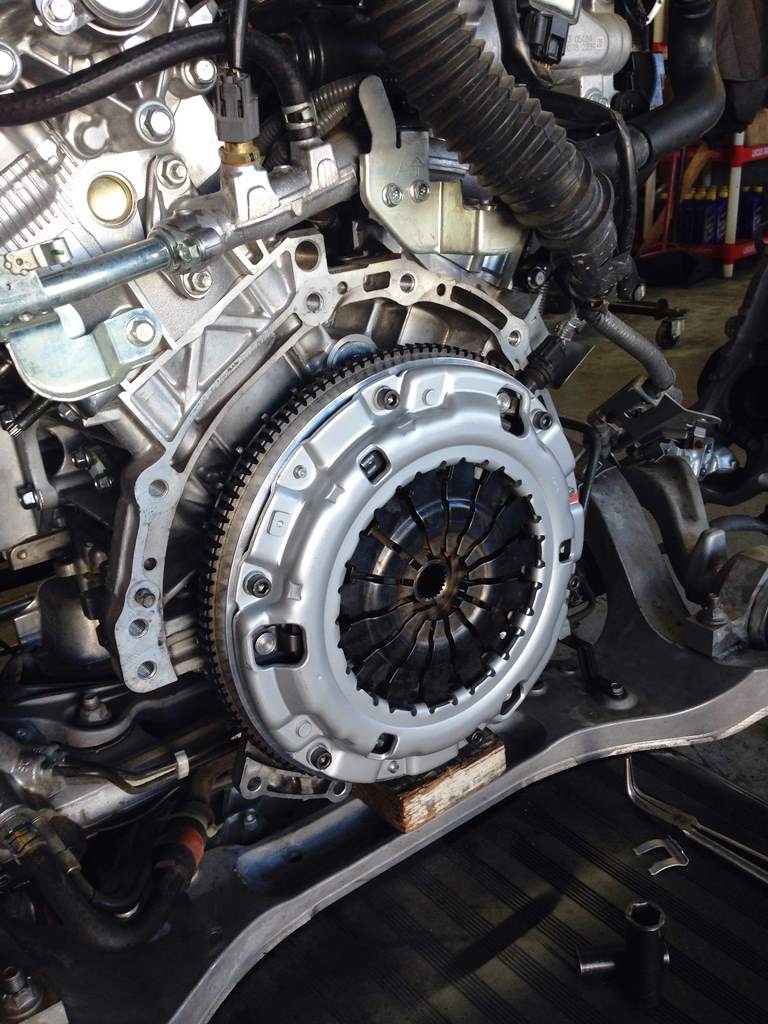

Our Max pressure plate bolted down.

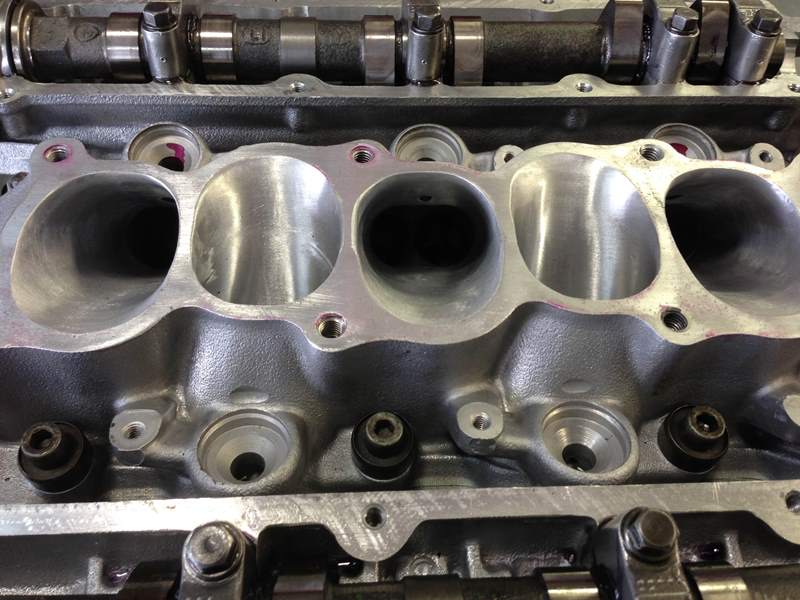

The Fast Intentions casted V-band exhaust manifolds for both the turbos and wastegates. Beautiful merge of all 3 cylinders as one can see.

The two stars of the show, Garrett GT2860RS turbos. Measuring 60mm on the exducer portion of the compressor wheel. The kits also ship with the oil drain fittings installed for less guessing. The fittings use an o-ring for sealing against the center section drain. Notice the elegant taper used on the Tial turbine housing. All this helps power and spool.

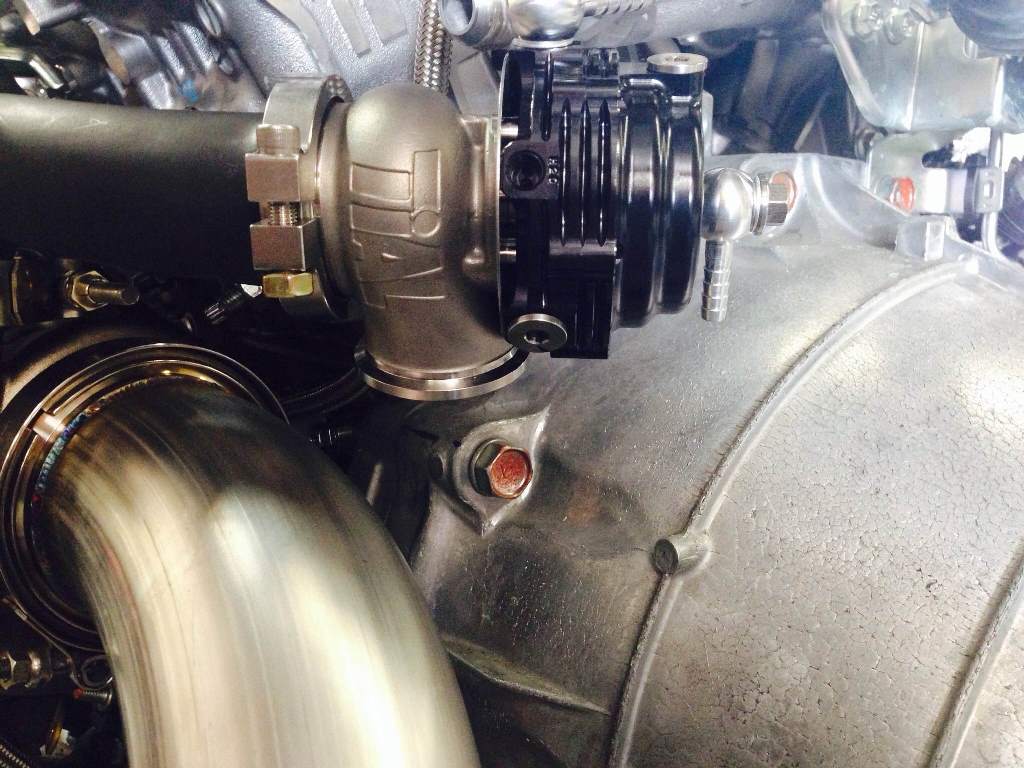

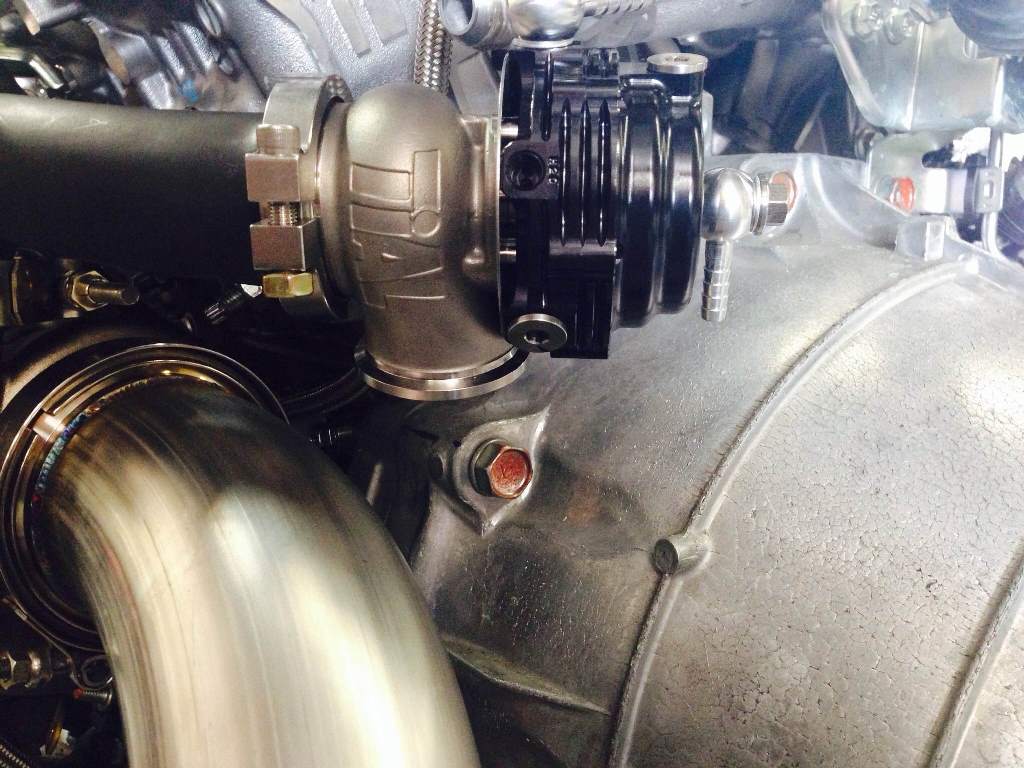

A good view of the Tial wastegate(s) used on the kit.

Passenger side of the kit installed.

Driver side of the kit installed.

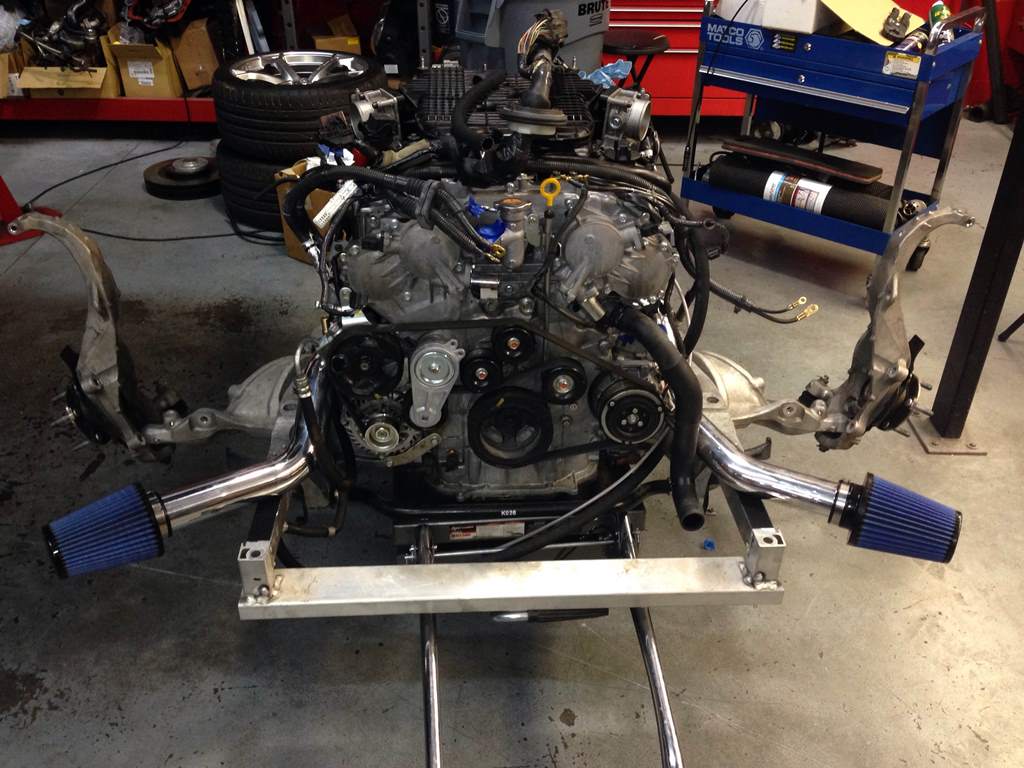

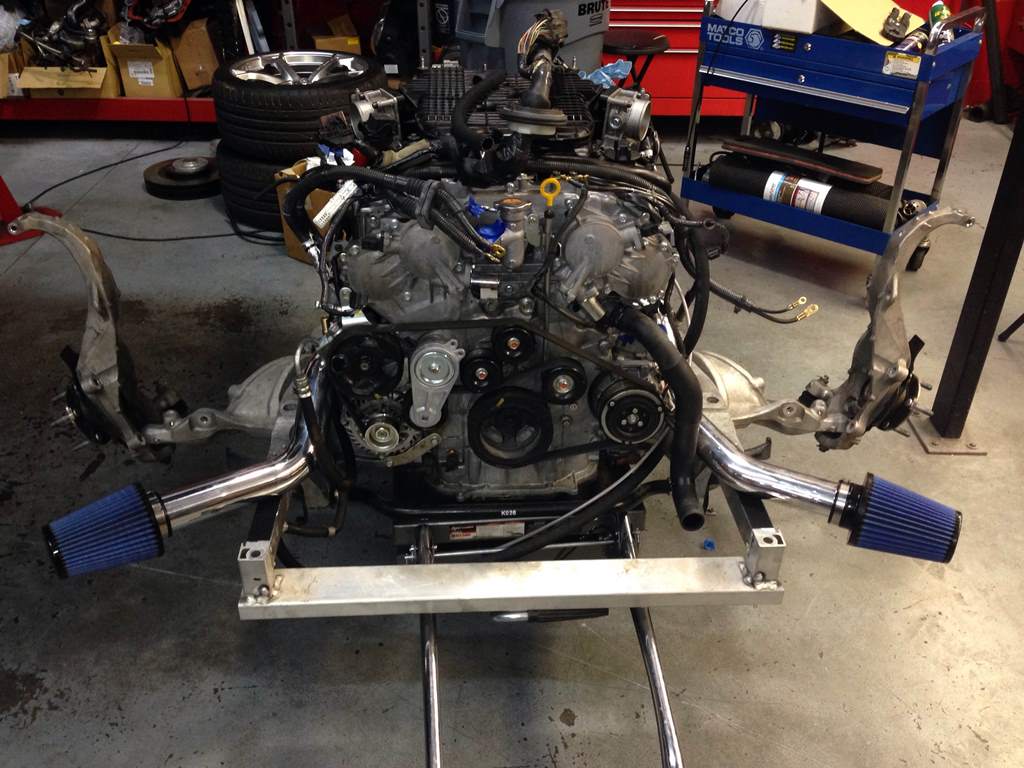

Ready to go back to its engine bay.

The kit makes use of the Greddy oil pan with the turbo oil drain fittings also already installed when one receives it. Also pictured is the engine oil filter relocation which is also part of the kit.

A must for any Z34 is removing the terrible squishy liquid filled differential bushings. Only one horizontal mount is used on the Z33s and Z34s which also makes things worse for movement and wheel hop.

Whiteline bushing in place ready to get pressed in further into the subframe.

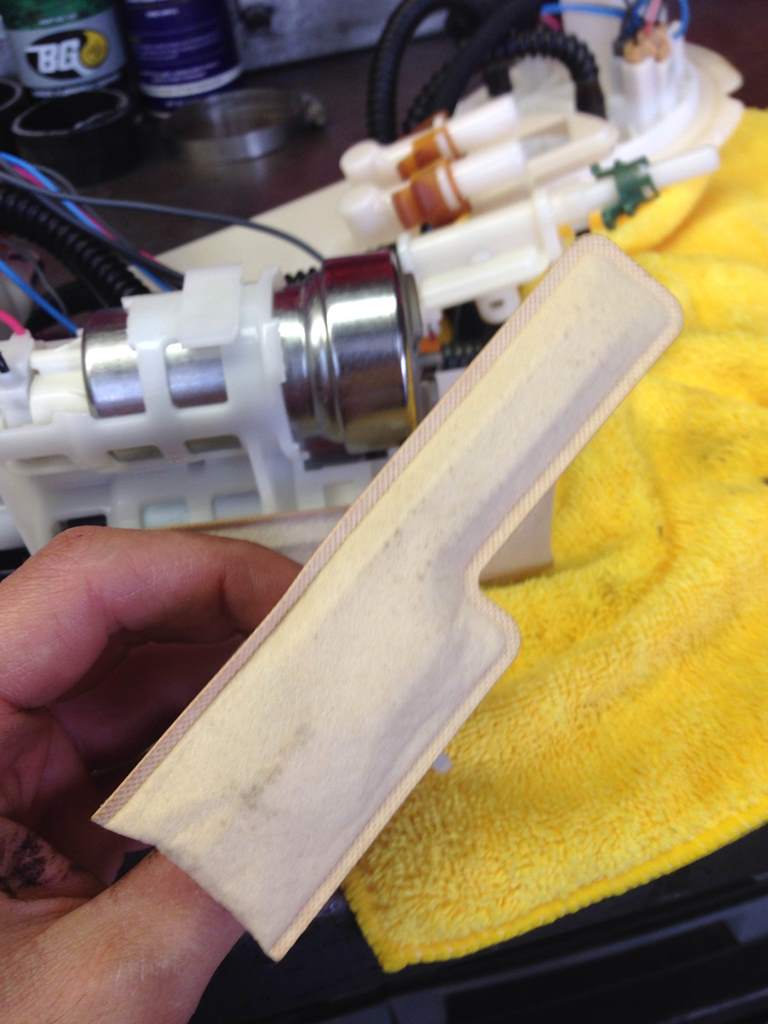

Intercooler looking mighty mean. The Tial BOVs are also easily mounted to the end tanks of the intercooler. This intercooler is actually separated in the middle and makes use of a divider plate to make sure all of the core(s) is used. Behind the intercooler is the Fast Intentions 34 Row Setrab oil cooler.

Here’s another view of the intercooler (not an actual picture of Bob’s NISMO). The intercooler brackets included in the kit are also already painted! Love that. Ready to bolt in and go, less install time, and more GO time!

A beautiful twinturbo kit for a beautiful Z.

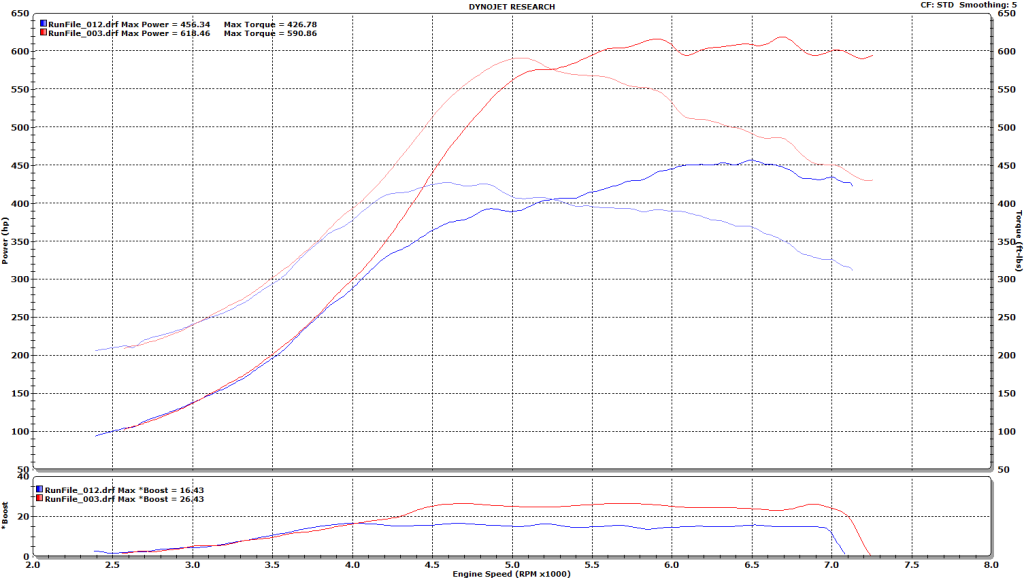

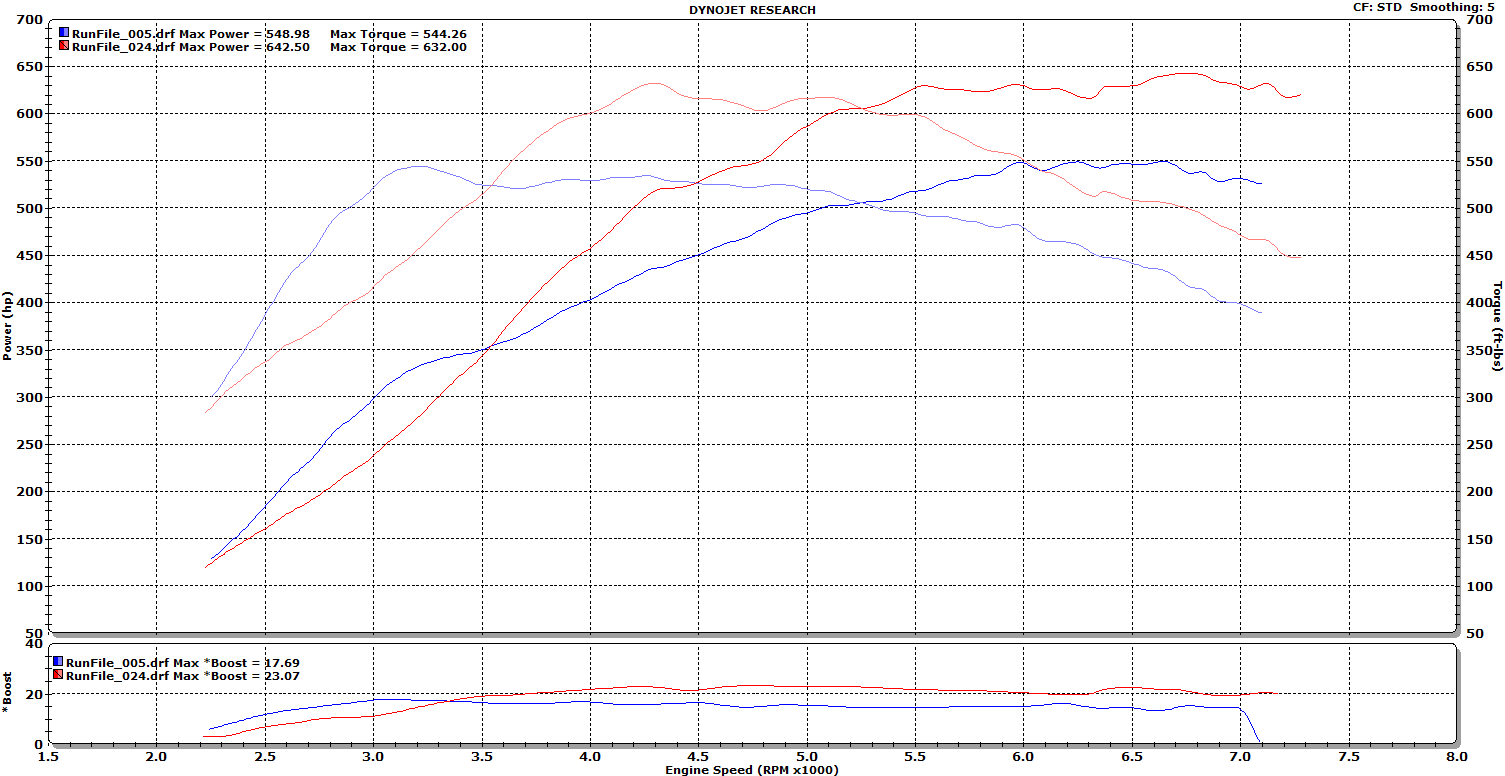

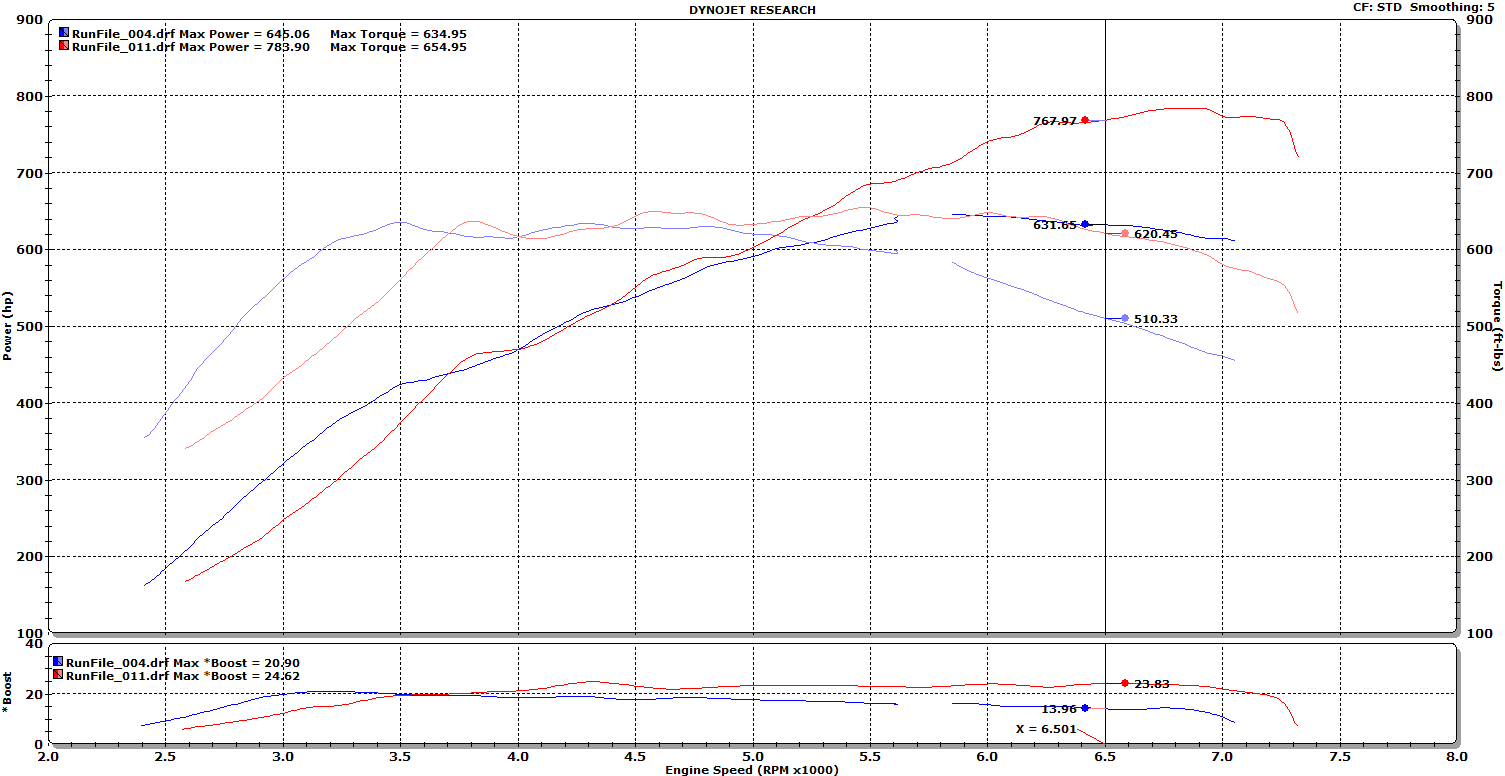

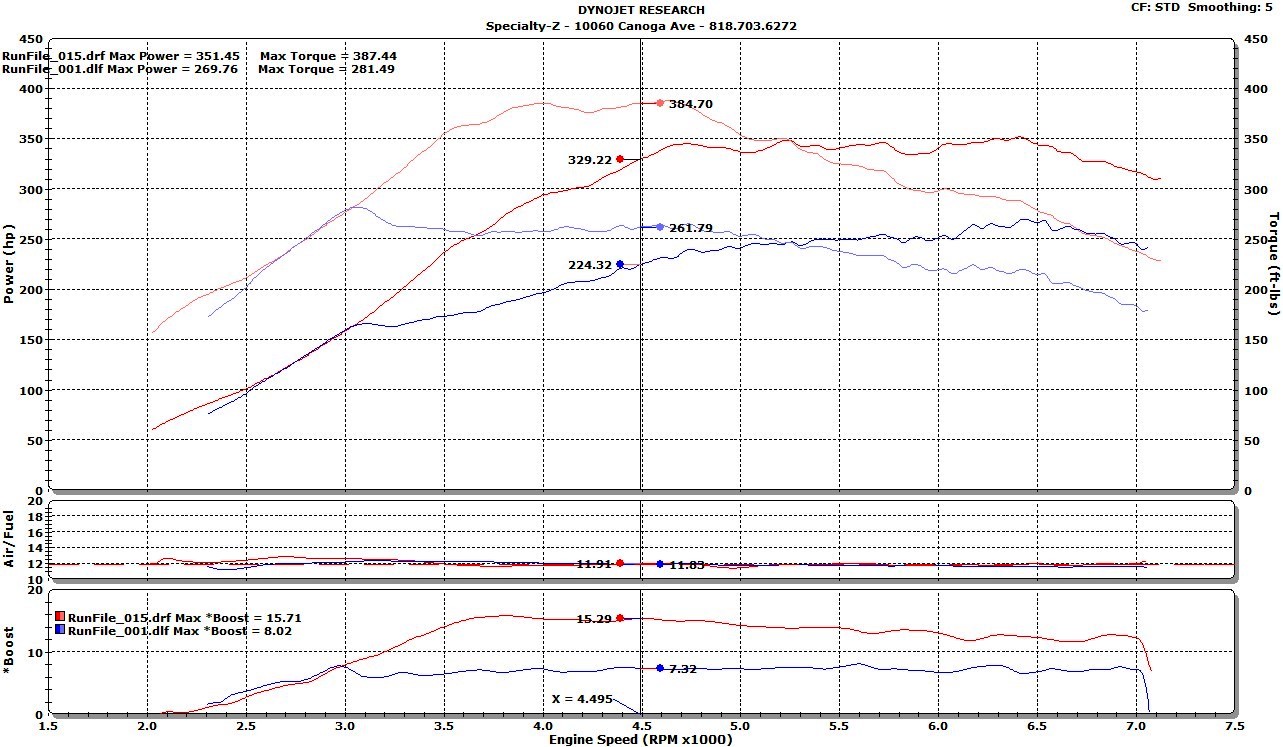

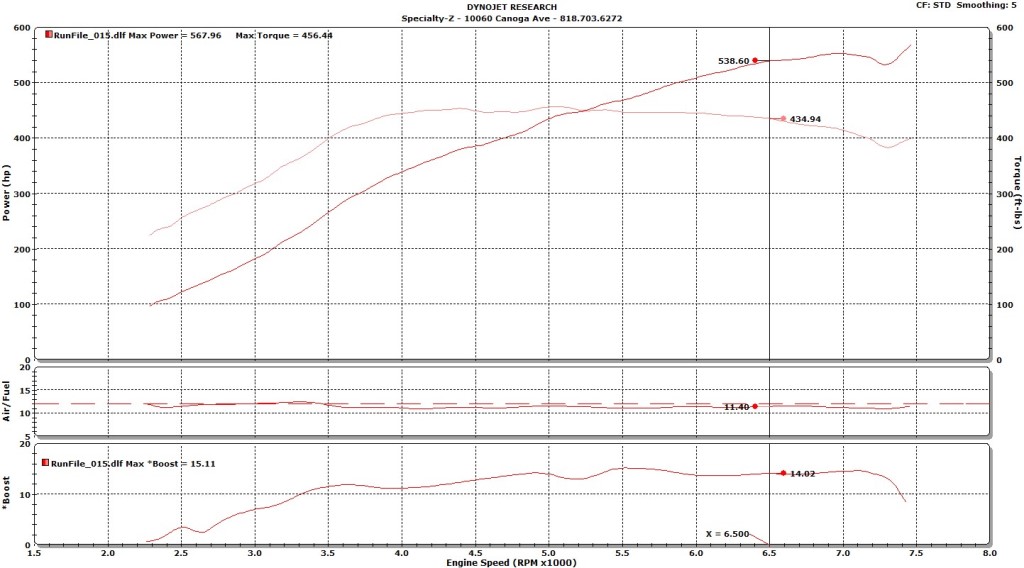

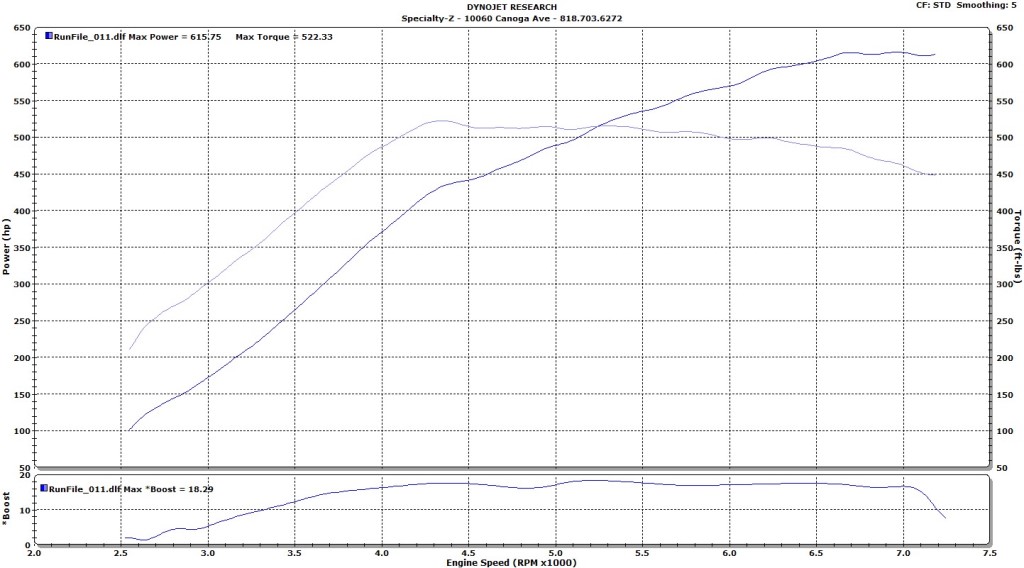

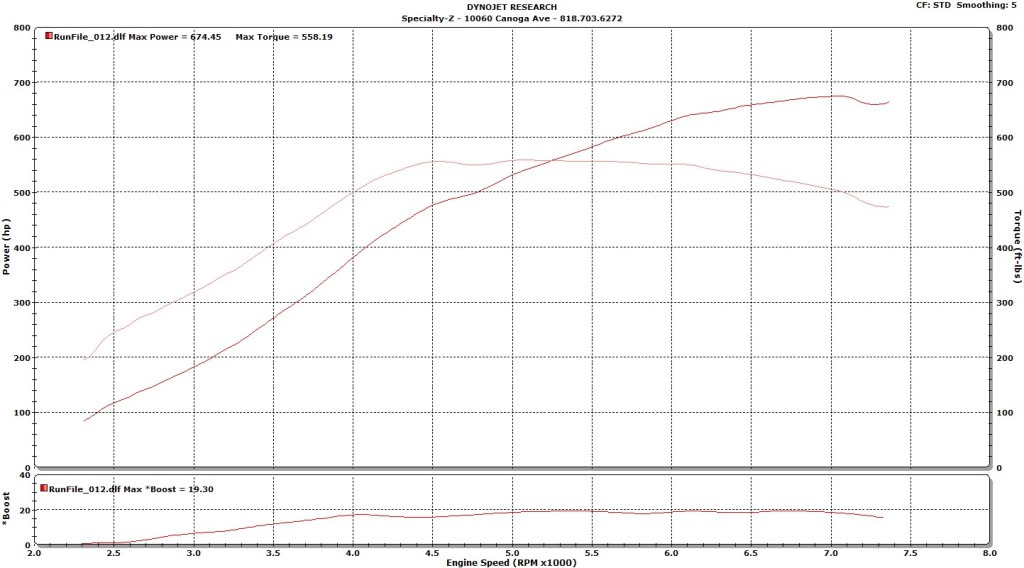

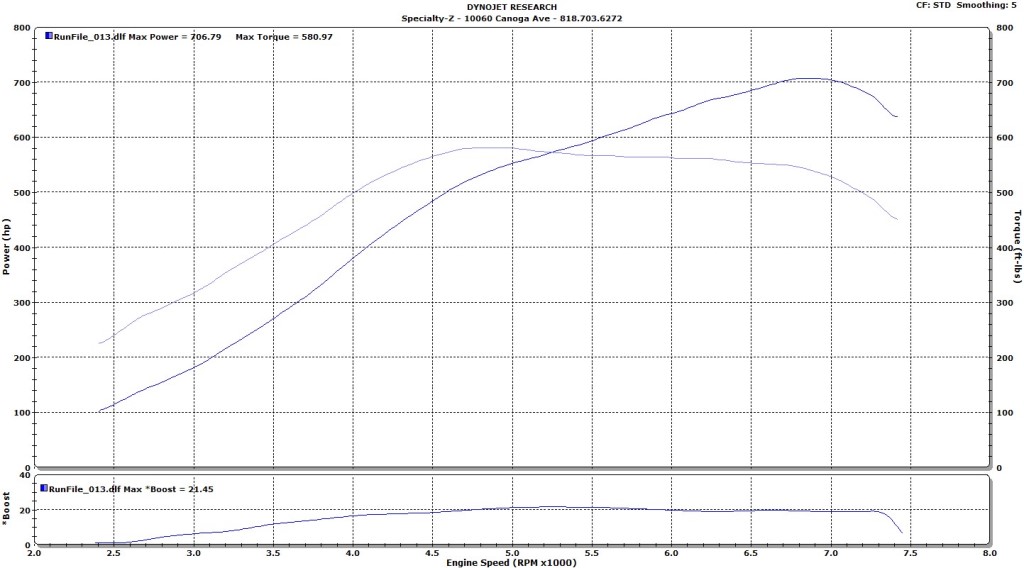

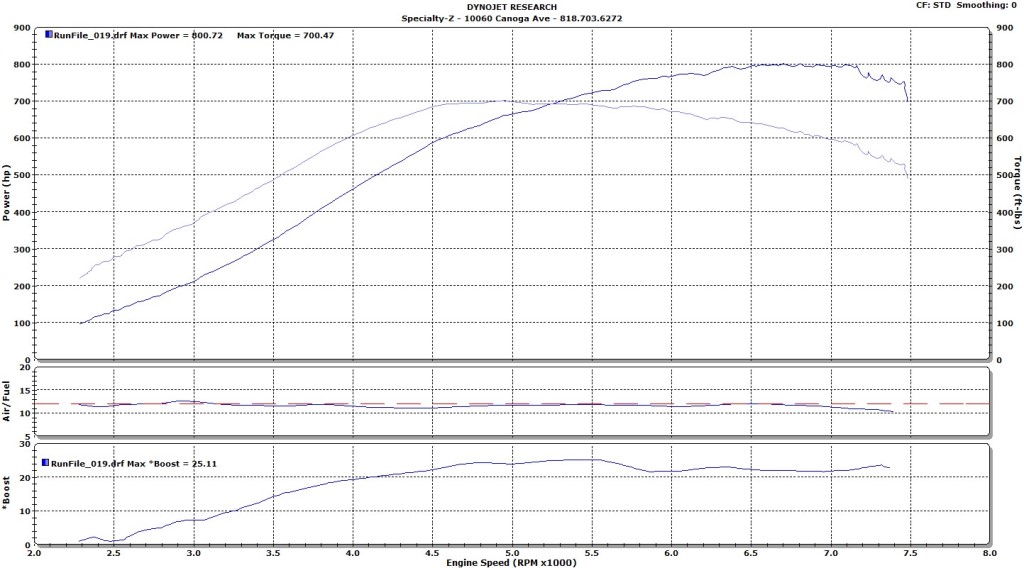

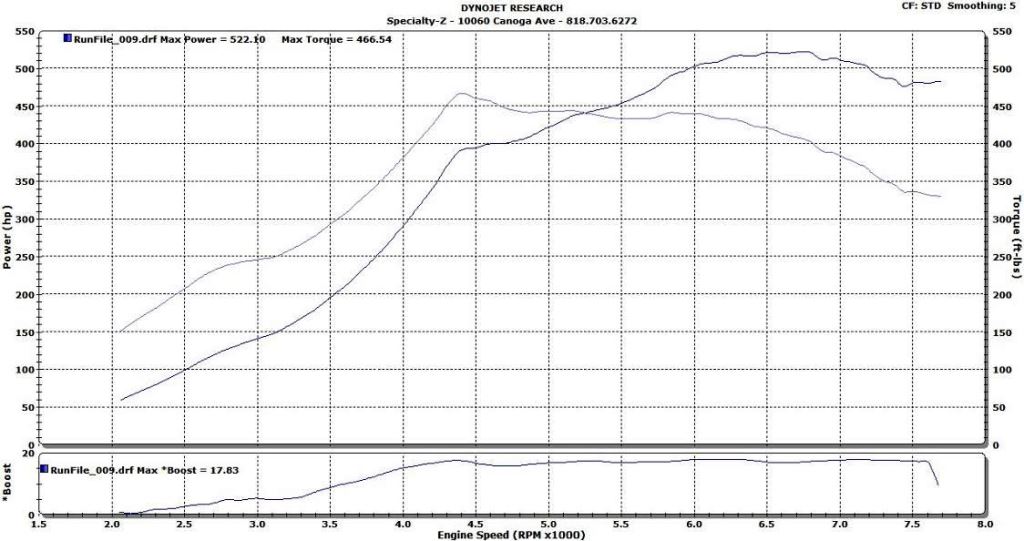

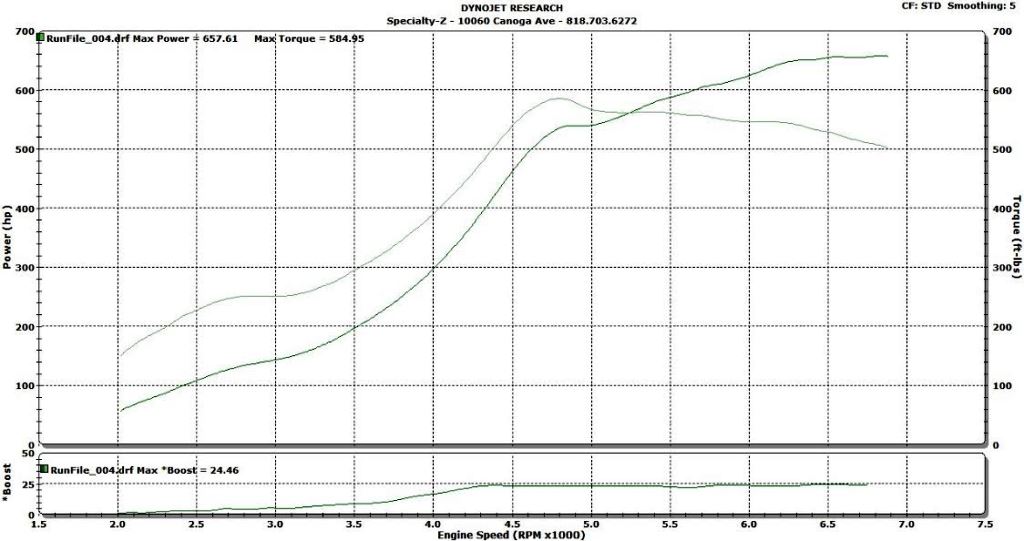

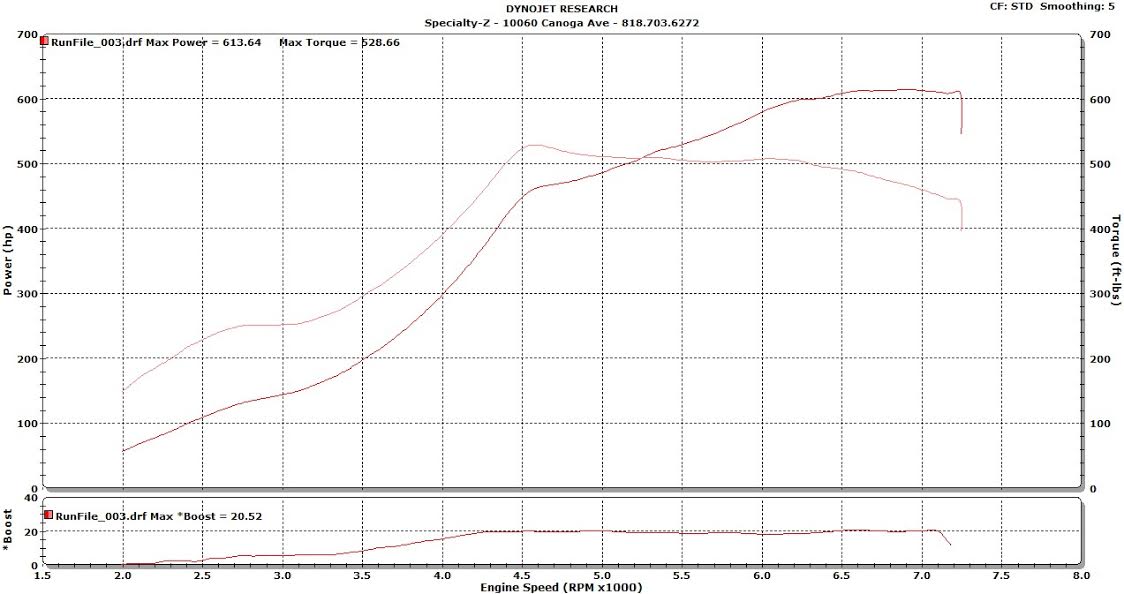

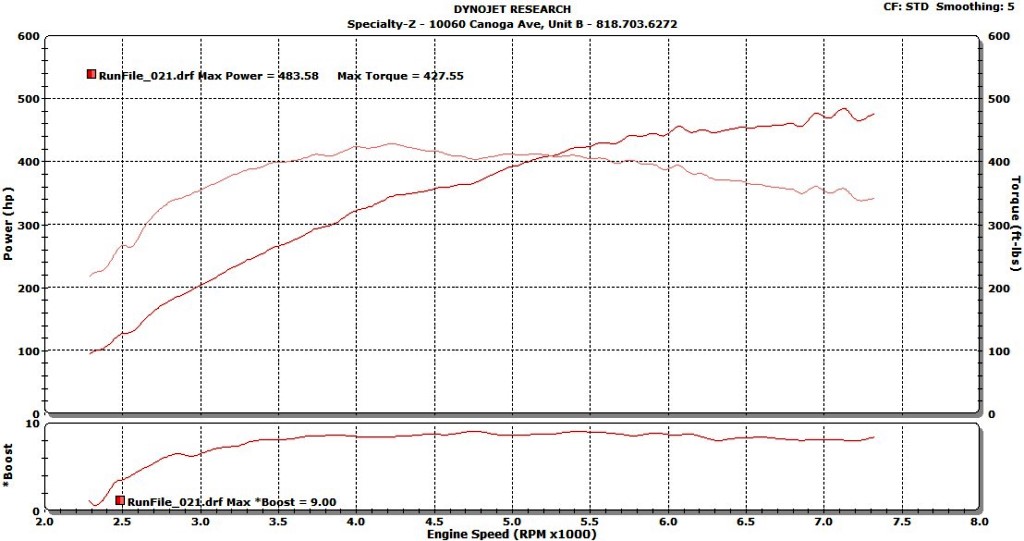

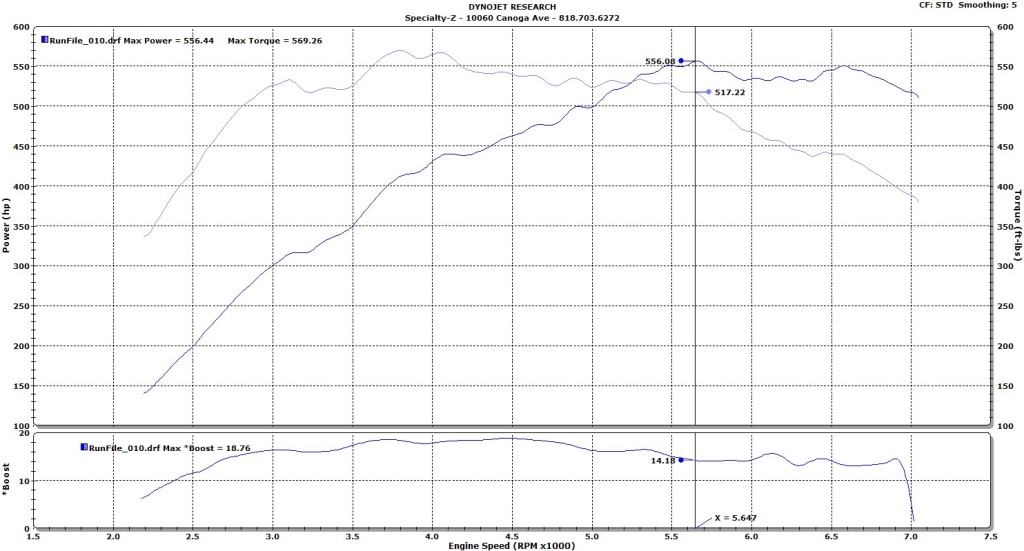

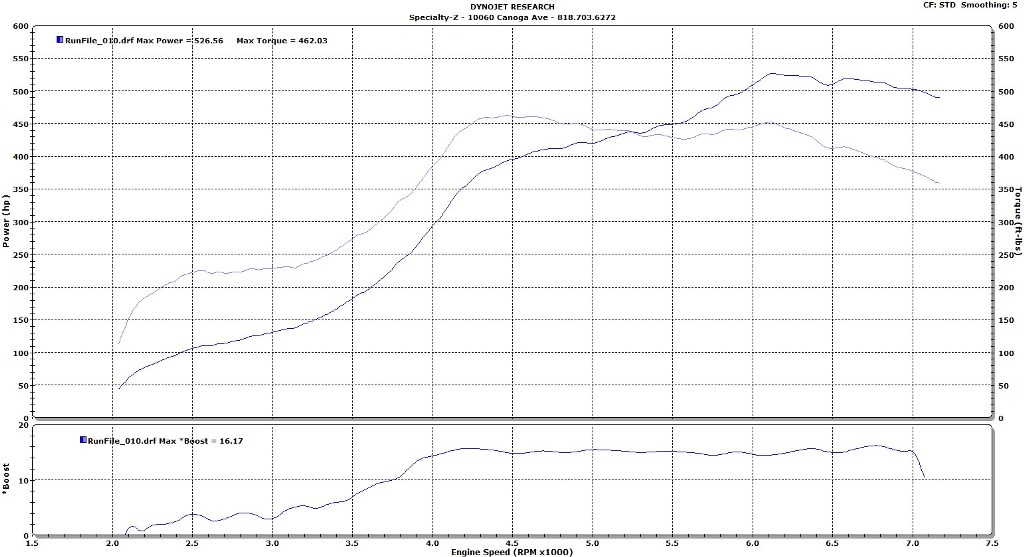

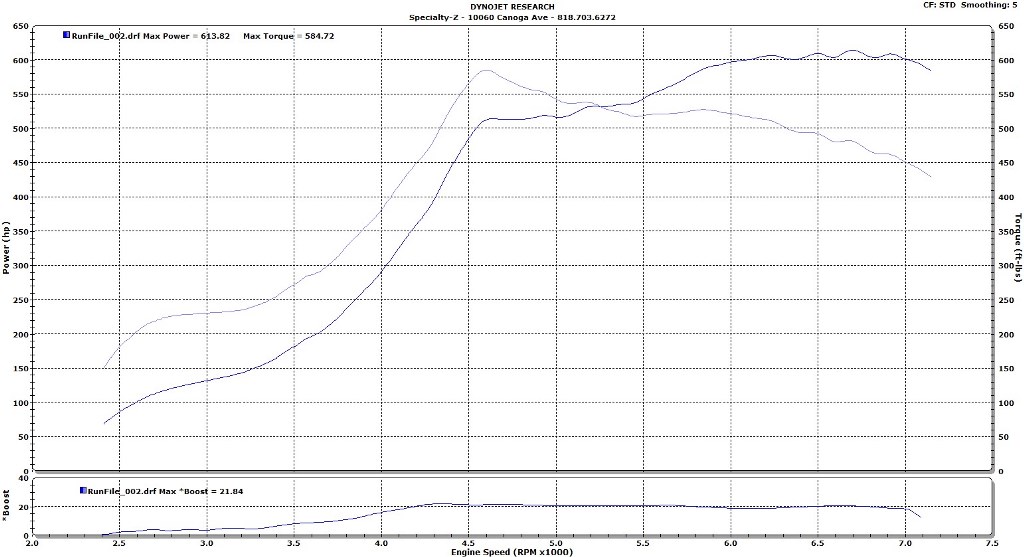

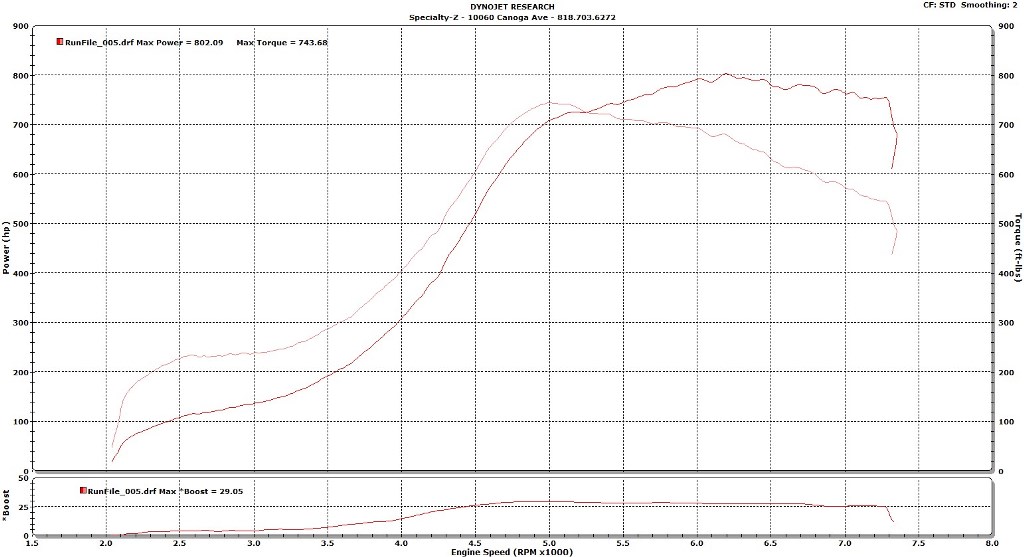

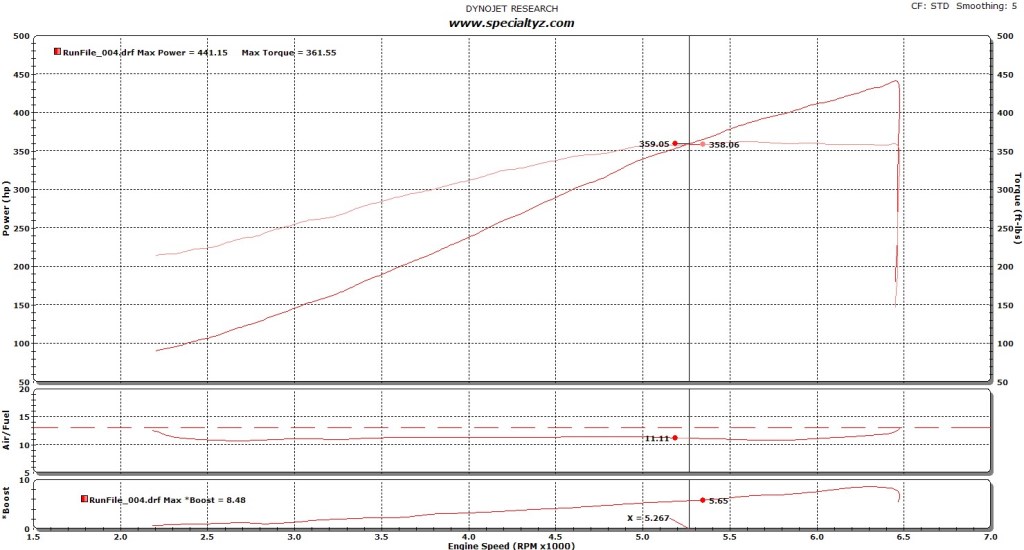

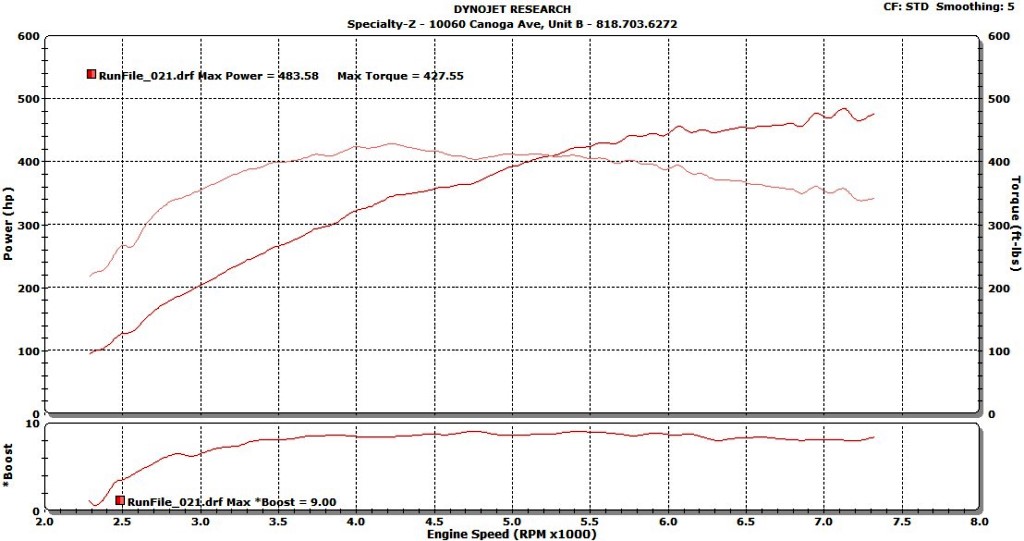

Last but not least our final power and torque numbers for 91 octane. We installed a Blitz sbc-iD Spec-R boost controller that works also as a boost gauge. An Innovate MTX Digital Wideband was also installed to monitor AFRs.